Umkhono wesihloko esibandayo uMenzi

Iimpawu zenkqubo yokubumba izihloko ezibandayo

1. Isihloko esibandayo senziwe kwiqondo lokushisa.Isihloko esibandayo sinokuphucula iimpawu zemishini yeendawo zetsimbi.

2. Inkqubo yokubumba izihloko ezibandayo inokunyusa izinga lenzala yezinto.Yindlela yoxinzelelo yomatshini esekwe kwi-deformation yeplastiki, enokuqonda ukusika okuncinci okanye ukungasikwa.Izinga lokusetyenziswa kwezinto ngokubanzi liku-85% ngaphezulu, elona liphezulu linokufikelela kuma-99% ngaphezulu.

3. Inokuphucula ukusebenza kakuhle kwemveliso.Ixesha lokuguqulwa kwemveliso yesinyithi kunye nenkqubo zifutshane, ngakumbi kwiindawo ezininzi zokulungisa umatshini wokwenza umatshini, unokuphucula kakhulu imveliso.

4. Itekhnoloji yokubumba ebandayo inokuphucula uburhabaxa bemveliso kwaye iqinisekise ukuchaneka kweemveliso.

Iimfuno zenkqubo yokubumba isihloko esibandayo kwimathiriyeli ekrwada

1. Ukwakhiwa kweekhemikhali kunye neempawu zomatshini wezinto eziluhlaza kufuneka zihlangabezane nemigangatho efanelekileyo.

2. Izinto ezikrwada kufuneka spheroidized unyango annealing, isakhiwo metallographic izinto inqanaba pearlite spherical 4-6.

3. Ubunzima bezinto eziluhlaza, ukwenzela ukunciphisa ukuthambekela kokuqhekeka kwezinto ngokusemandleni kunye nokuphucula ubomi benkonzo yesikhunta, izinto ezibandayo ezibandayo zifunekayo ukuba zibe nobunzima obuphantsi kunokwenzeka ukuphucula iplastiki.Ubunzima bezinto eziluhlaza bufuneka ngokubanzi ukuba bube kwi-HB110~170 (HRB62-88).

4. Ukuchaneka kwezinto zokudweba ezibandayo kufuneka kunqunywe ngokweemfuno ezithile zemveliso kunye nenkqubo.Ngokuqhelekileyo, ukuchaneka kwe

5. Umgangatho womphezulu wezinto ezibandayo zomzobo ufuna ukuba ifilimu yokuthambisa ibe mnyama, kwaye umphezulu awuyi kuba nemikrwelo, ukugoba, ukuqhekeka, iinwele, umhlwa, ulusu lwe-oxide kunye nemingxuma kunye nezinye iziphene.

6. Ubunzima bubonke boluhlu lwe-decarburization kwicala le-radius ye-draining material ebandayo akufanele idlule i-1-1.5% yobubanzi bezinto eziluhlaza (imeko ethile ixhomekeke kwiimfuno zomenzi ngamnye).

7. Ukuze kuqinisekiswe umgangatho wokusika wokubumba okubandayo, izinto zokudweba ezibandayo ziyafuneka ukuba zibe nobuso obunzima kunye ne-soft core state.8. Uvavanyo lwe-cold-top forging kufuneka lwenziwe kwizinto ezitsalwa ngokubanda, kwaye uvakalelo lwezixhobo ekusebenzeni nzima okubandayo kufuneka lube luphantsi kangangoko, ukuze kuncitshiswe ukwanda kokumelana ne-deformation ngenxa yokuqina okubandayo ngexesha. deformation.

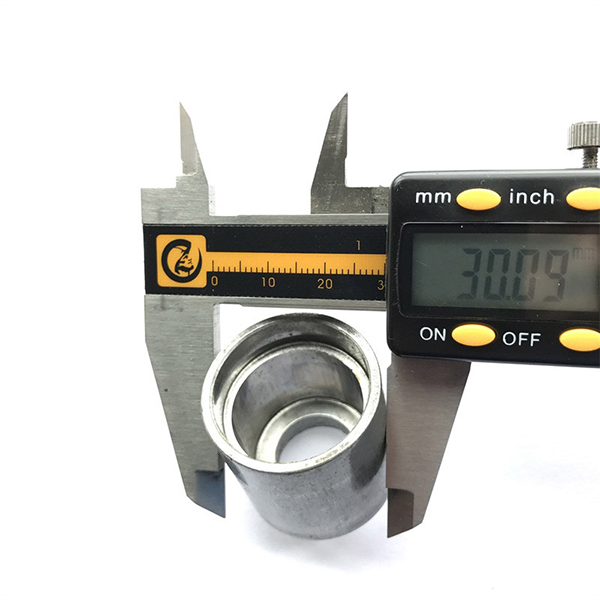

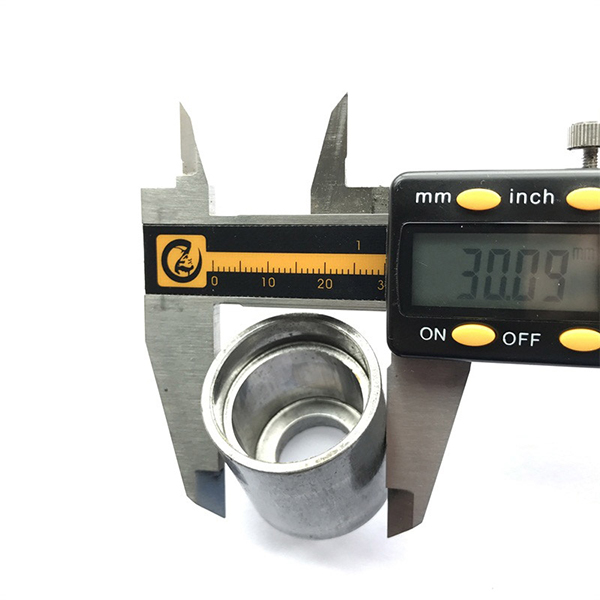

Umboniso weMveliso